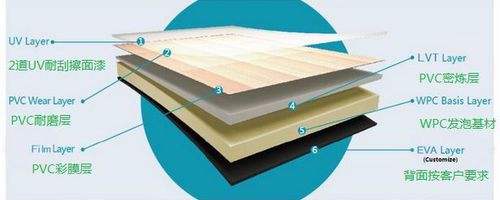

WPC wood plastic flooring production line

Production specification: thickness: (2mm-12mm) x970mm * 2000mm flooring substrate or 1220*2440

PVC floor substrate production line is composed of extruder, mold, foam plate molding machine, natural cooling system, tractor, a new generation of finishing automatic fixed length cutting machine (frequency conversion speed regulation), automatic finished product unloading table, turnover carriage.

Process flow of PVC wood plastic flooring substrate

1. Raw materials

Prepare raw materials, PVC resin, wood flour, straw, light calcium carbonate and other chemical auxiliaries.

2, mixed

(1) according to the formulation requirements, manual operation should be done for metering formula proportioning, and the measurement must be accurate.

(2) After the metering, start the high-speed mixer, put all the metered raw materials into the high-speed mixer, mix for about 15 minutes.

3, feeding (using equipment: Loader)

The uniformly mixed material is fed into the hopper of the extruder through a screw automatic feeding machine.

4. Extrusion plasticizing (use of equipment: twin screw extruder)

The extruder is preset and insulated. The setting temperature is about 170 C. Material put into the hopper of the extruder is melted and plasticized through the extruder and extruded into the vacuum setting device through the die.

5, cooling setting (use equipment: vacuum setting parts).

The material extruded by the extruder die head is sent to the vacuum setting device and cooled by circulating cooling water.

6, traction (use equipment: Tractor)

The cooling and stereotyped wood plastic plate is drawn through the traction machine and sent to the cutting machine.

7, cutting (using equipment: cutting machine)

The wood-plastic Board sent to the cutting machine is cut into the required length, and the cut wood-plastic board is arranged on the tray in order, and the height can not exceed 1 meter.

|

Model |

Thickness(mm) |

Width(mm) |

Power(kw) |

Max capacity(kg/h) |

|

80/156 |

3-5 |

1050 ,1350 |

75 |

300 |